Tungsten Carbide Milling Cutter

Product Details:

- Tungsten( in %) 99.95

- Carbon % 0.05

- Application Milling Cutter,elimination of ice deposit, rubber deposit and line markings of thermoplastic

- Warranty as per the contract

- Click to View more

Tungsten Carbide Milling Cutter Price And Quantity

- 1 USD ($)

- 1 Piece

Tungsten Carbide Milling Cutter Product Specifications

- Milling Cutter,elimination of ice deposit, rubber deposit and line markings of thermoplastic

- as per the contract

- 0.05

- 99.95

Tungsten Carbide Milling Cutter Trade Information

- Guangzhou

- Cash Advance (CA) Cash in Advance (CID)

- 1000kg Per Month

- 4 Week

- Yes

- Contact us for information regarding our sample policy

- wooden box

- Australia Middle East Western Europe

- East India

- ISO9001

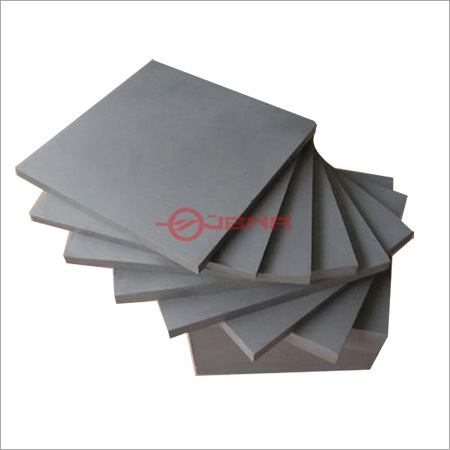

Product Description

Features

- Long working life

- Application specific design

- High production rate

- Hassle free operation

This cutter is utilized for elimination of ice deposit, rubber deposit and line markings of thermoplastic.

Technical Specification :

| Grade | Density | T.R.S | Hardness | Performance & Application Recommended | Approx | ISO |

| MK6A | 14.9 | 1860 | 92.0 | Fine grain size and unique wear resistance capacity. Utilized for alloy steel, semi finishing work of chilled cast iron, finishing and semi finishing of hardened steel, non ferrous metal alloys. | YG6A | K10 |

| MK8 | 14.7 | 2320 | 89.5 | Exceptional strength, higher shock and impact resistance capacity than MK 6A, although its cutting speed and wear resistance ability is lower than MK 6A.Utilized for roughing work for non ferrous metal, alloy metal, cast iron and non metal items at low working speed. | YG8A | K20 |

| MK10X | 14.5 | 2150 | 91.0. | Known for uniform and fine grain size and good wear resistance capacity. Utilized for processing of PVC, veneer board, metals and PCB. | - | K10-K20 |

| YS2T | 14.5 | 2350 | 92.0 | Superior grade alloy, good bonding resistance capacity, wear proof design, exceptional thermal strength and unique bending capacity. Utilized for machining of stainless steel, refractory alloy and high manganese steel. | YS2T | K10-K20 |

| SL10 | 14.8 | 2420 | 90.5 | Good bending capacity and wear proof design. It acts as lead cutter used in electric industry. | - | K20-K30 |

| G20 | 14.3 | 2360 | 90.0 | High wear resistance capacity and good bending resistant performance. Suitable for steel alloy. | - | K20-K3 |